Among the essential components of any industrial setup are the displays that provide crucial data to operators. These industrial displays must withstand some of the harshest environments, from extreme temperatures and heavy vibrations to dust, moisture, and corrosive substances.

Industrial displays are not just regular screens; they are sophisticated pieces of technology designed to endure and perform under conditions that render ordinary consumer-grade liquid-crystal displays useless. This article explores the key features that make industrial displays suitable for demanding applications.

Why Choose an Industrial Touch Monitor?

Industrial touch monitors offer a seamless blend of durability and functionality, making them ideal for harsh environments. With features like glove-friendly touchscreens, high brightness for readability in direct sunlight, and robust housings made from stainless steel or aluminum, industrial display monitors are built to endure and excel where standard monitors fail.

Key Differences Between Consumer and Industrial Monitors

Consumer and industrial monitors are built with distinct purposes, leading to several key differences in design, functionality, and durability. Consumer monitors, commonly used in homes and offices, prioritize high resolution, sleek design, and cost-effectiveness. However, such personal computers lack the robustness required for industrial environments.

Industrial PCs, on the other hand, are engineered to withstand extreme conditions. They are built with rugged materials such as stainless steel or aluminum, often featuring reinforced glass to protect against impacts and vibrations.

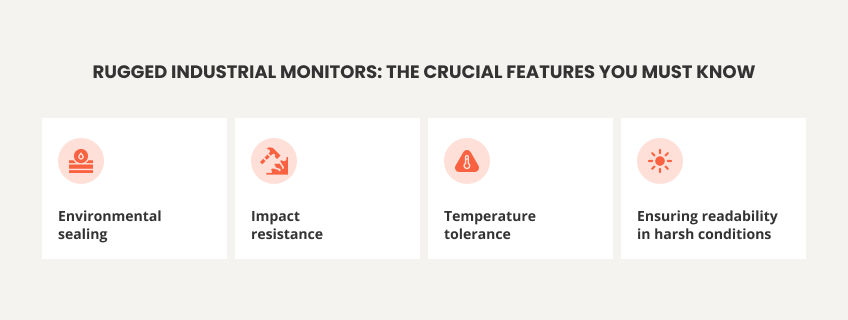

Rugged Industrial Monitors: The Crucial Features You Must Know

Environmental sealing

One of the most critical features of rugged industrial monitors is their ability to withstand harsh environmental conditions through effective sealing. Industrial monitors often adhere to stringent IP (Ingress Protection) ratings, with IP65 and IP67 being common standards. These ratings indicate that industrial panel mount monitors are dust-tight and can withstand water jets or immersion in water, making them suitable for environments like manufacturing plants, oil rigs, and outdoor installations where exposure to elements is a concern.

Impact resistance

In industrial settings, monitors are often subjected to rough handling, accidental impacts, and vibrations from heavy machines. Therefore, impact resistance is a crucial feature of rugged industrial monitors. These monitors are built with reinforced materials such as tempered glass or polycarbonate screens that resist shattering.

The chassis is typically constructed from robust metals like stainless steel or aluminum, providing a sturdy frame that can absorb and dissipate shocks. Some monitors feature rubberized or cushioned exteriors to further protect against impacts. This durability ensures that the monitors can maintain their integrity and functionality even in the most demanding environments, reducing downtime and maintenance costs.

Temperature tolerance

Temperature extremes are a common challenge in industrial environments, whether it’s the freezing temperatures in cold storage facilities or the intense heat in metal foundries. Rugged industrial monitors are designed to operate reliably across a broad temperature range. These monitors incorporate components rated for extended temperature ranges, often from -20°C to 70°C or more.

Ensuring readability in harsh conditions

For environments with variable lighting, monitors may feature brightness adjustment automation, ensuring optimal visibility at all times. Rugged industrial monitors often offer wide viewing angles and high contrast ratios, allowing operators to read critical information from various positions and under different lighting conditions. This readability is key to maintaining efficiency and safety, as clear data visibility is vital in potentially hazardous industrial settings.

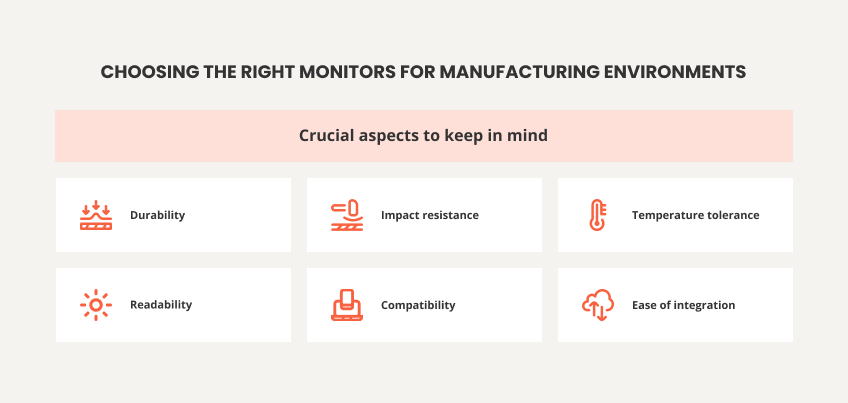

Choosing the Right Monitors for Manufacturing Environments

When selecting industrial computer monitors for manufacturing environments, it’s essential to consider several key factors to ensure optimal performance and longevity. These monitors must withstand harsh conditions and provide reliable operation to support critical manufacturing processes. Below are the crucial aspects to keep in mind:

- Durability: Prioritize monitors with robust construction and high IP ratings to withstand dust and moisture.

- Impact resistance: Look for impact-resistant screens and sturdy housings that can endure the rigors of daily use.

- Temperature tolerance: Ensure the monitors can operate reliably in facilities with fluctuating or extreme temperatures.

- Readability: Opt for monitors with high brightness and anti-glare features for clear visibility under varied lighting conditions.

- Compatibility: Check for compatibility with existing systems to ensure seamless operation and minimal downtime.

- Ease of integration: Choose monitors that are easy to integrate into your current setup for efficient and uninterrupted use.

Benefits of Using Industrial-Grade Touchscreen Displays

Supervisory control and data acquisition (SCADA)

Industrial-grade touchscreen displays are crucial in Supervisory Control and Data Acquisition (SCADA) systems. SCADA systems are used to monitor and control industrial processes, ensuring real-time data acquisition and management. Touchscreens provide an intuitive interface for operators to monitor system performance, manage alarms, and control processes with ease.

The visual representation of data through graphs, charts, and other graphical elements allows for quick assessment and decision-making. The reliability and precision of industrial touchscreens ensure operators can effectively manage complex systems, minimizing downtime and optimizing productivity.

Security

Security is a significant concern in industrial environments, and industrial-grade touchscreen displays contribute to enhancing it. These displays often come with advanced security features such as encrypted communication, user authentication, and access control. By integrating biometric scanners or RFID readers, the industrial monitors’ touchscreens can ensure that only authorized personnel can access sensitive controls and data.

Touchscreen capabilities

The touchscreen capabilities of industrial-grade displays are tailored to meet the demands of harsh environments. These industrial touchscreens are designed to be responsive even when operators wear gloves, a common requirement in many industrial settings. Multi-touch functionality allows for advanced gesture controls, improving the efficiency and speed of operations.

Capacitive touch technology, commonly used in these displays, provides a durable and accurate touch experience. The rugged nature of these touchscreens ensures they remain functional in conditions involving dirt, moisture, and extreme temperatures, providing a reliable user interface under all circumstances.

Connectivity and integration

Industrial-grade touchscreen displays are designed with extensive connectivity options to integrate seamlessly with other industrial systems and devices. They support various communication protocols such as Ethernet, RS232, RS485, and USB, enabling easy connection with PLCs, sensors, and other control systems. This connectivity facilitates real-time data exchange and centralized control, essential for modern industrial operations. These displays often support IoT (Internet of Things) integration, allowing advanced data analytics and remote monitoring.

User-friendly design

User-friendly design is a hallmark of industrial-grade touchscreen displays. Customizable interfaces allow tailoring control panels to specific needs, enhancing the efficiency of operations. The ergonomic design of these displays ensures that they can be comfortably used for extended periods, reducing operator fatigue. By providing a user-centric design, industrial touchscreens enhance overall productivity and job satisfaction.

Case Studies and Applications

Advanced display systems have become essential across various sectors. These systems enhance operational efficiency and ensure precision and safety in demanding environments. Below are some case studies and applications demonstrating how real-time data displays and rugged interfaces are optimizing production processes and improving overall efficiency in diverse industries:

- Automotive manufacturing: Real-time data displays optimize production lines, reducing downtime and improving efficiency.

- Pharmaceuticals: Rugged displays ensure precision in process monitoring under stringent conditions.

- Energy plants: Enhanced SCADA interfaces offer better control and safety management.

- Logistics: Clear, real-time tracking and management of supply chains improve operational efficiency.

- Food and beverage: Industrial displays monitor critical parameters to maintain quality and compliance with safety standards.

- Aerospace: High-resolution displays provide crucial data for manufacturing complex components with the utmost accuracy.

- Mining: Durable displays withstand harsh conditions while providing vital data for safe and efficient operations.

Kiosks with Industrial Touchscreens by friendlyway

friendlyway’s kiosks with industrial touchscreens are designed for robust performance in demanding environments. These monitors feature high durability with ruggedized exteriors, ensuring dust, moisture, and impact resistance. With advanced touch technology, including glove-friendly and multi-touch capabilities, they provide intuitive and responsive interaction even in harsh conditions.

Industries We Serve

Our cloud-native platform and digital signage hardware solutions are versatile and can be deployed across various industries and business scenarios. We proudly serve the following sectors:

- Manufacturing

- Government and public services

- Travel and hospitality

- Education

- Healthcare and life sciences

- Financial services

- Energy and utilities

- Logistics and transportation

- Retail

- Staffing and recruiting

Conclusion

The right data display technology choice can significantly impact productivity, efficiency, and safety. Industrial-grade touchscreen monitors stand out as essential tools, offering robust features such as environmental sealing, impact resistance, temperature tolerance, and superior readability.

Their advanced touch capabilities, enhanced security, and seamless connectivity further underscore their importance in modern industrial settings. Companies like friendlyway provide solutions that meet these stringent requirements, delivering reliable and efficient interfaces that withstand harsh conditions.

By integrating these monitors into operations, industries can ensure reliable performance, intuitive control, and a user-friendly experience.

FAQ

Industrial computer monitors are specialized displays designed for use in harsh and demanding environments. Unlike consumer-grade monitors, these displays are built to withstand extreme temperatures, dust, moisture, vibrations, and impacts. They feature robust construction, advanced touch technology, and enhanced connectivity options to support various industrial applications, ensuring reliable performance and longevity.

Choose an industrial monitor that withstands rough handling, operate across a wide temperature range, offer high brightness and anti-glare features for clear visibility, ensure system compatibility, and are easy to install and integrate.

Investing in a properly specified industrial display screen offers enhanced durability for reliable operation, improved efficiency with clear data for quick decision-making, increased safety through robust construction and secure interfaces, and long-term cost savings by reducing the need for frequent replacements.

Rugged industrial display screens, made of durable materials like tempered glass, resist impacts, vibrations, and contaminants. They operate reliably across wide temperature ranges and feature glove-friendly, multi-touch capabilities for accurate performance in harsh conditions.

Touchscreens for hazardous environments need to be explosion-proof (e.g., ATEX, IECEx certified), have robust construction to withstand harsh conditions, and a sealed design with high IP ratings. They should offer advanced security features like user authentication and encrypted communication, and ensure reliable performance and accuracy under demanding conditions for continuous operation and safety.