Integrating digital signage in manufacturing facilities will significantly enhance operational efficiency and communication. By strategically placing digital displays throughout the plant, companies can streamline information dissemination, improve safety protocols, and boost employee engagement. These dynamic screens offer real-time updates on production metrics, safety alerts, and company news, ensuring everyone in the organization is informed and aligned with business goals.

Digital signage can reduce perceived downtime by providing engaging content and training materials. This article explores the various strategies for implementing digital signage in manufacturing environments and highlights the numerous benefits, from improved productivity to enhanced workplace morale. Read on to learn more.

Understanding Digital Signage

Definition and components

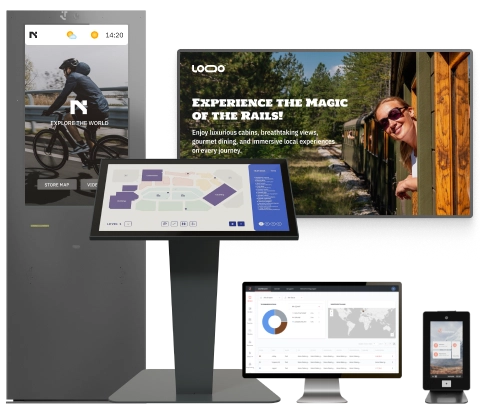

Digital signage refers to the use of digital displays, such as LCD, LED, or projection screens, to convey information, advertisements, or other content. These displays are often networked and centrally managed, allowing real-time updates and content changes. The primary components of a digital signage system include the display screens, media players, content management software, and network connectivity.

Types of digital signage

Digital signage can be categorized into several types based on relevant applications and settings:

- Informational signage: In public places like airports, hospitals, and malls, these displays provide real-time information such as schedules, directions, and announcements.

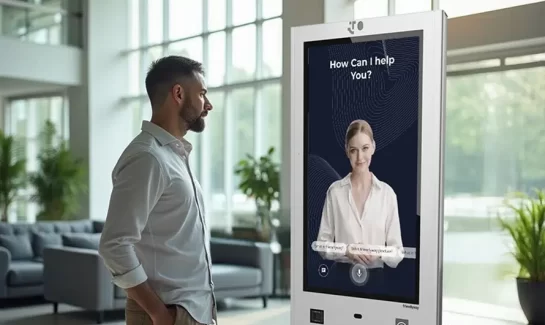

- Advertising signage: Found in retail environments, these screens promote products and services, enhancing customer engagement and driving sales.

- Interactive signage: Touchscreen displays allow users to interact with the content, commonly seen in kiosks and wayfinding stations.

- Menu boards: Utilized in restaurants and cafes, digital menu boards showcase menu items, prices, and promotions in a visually appealing manner.

- Corporate signage: Deployed within office environments to communicate company news, performance metrics, and employee information.

Benefits of Integrating Digital Signage in Manufacturing

Operational efficiency

Integrating digital signage into manufacturing facilities significantly enhances operational efficiency. Digital displays can streamline operations by providing real-time updates on production schedules, inventory management software, and machine statuses. For instance, if a machine goes down, a digital sign can immediately alert the maintenance team, reducing downtime and preventing bottlenecks. You can use digital signage solutions to display lean manufacturing principles and continuous improvement metrics, fostering a culture of efficiency and productivity.

Communication

Effective communication protocols are crucial in any manufacturing environment. Digital signage offers a dynamic and versatile communication platform that ensures all employees receive consistent and timely information. Traditional methods, such as bulletin boards or email, often fail to reach everyone promptly or may become outdated. Digital signage overcomes these limitations by delivering real-time updates, company announcements, and policy changes directly to the workforce.

Safety measures

Safety is a top priority in manufacturing facilities, and digital signage is key to enhancing workplace safety. In an emergency, you can use digital signage to broadcast urgent messages and evacuation procedures, ensuring a swift and coordinated response. Furthermore, digital signs can display safety metrics, such as the number of days since the last accident, promoting a safety-conscious culture among employees.

Real-time performance monitoring

Real-time performance monitoring is another benefit of digital signage in manufacturing. By integrating digital displays with manufacturing execution systems (MES) and other data sources, companies can provide real-time visibility into production performance. Metrics such as overall equipment effectiveness (OEE), cycle times, and defect rates can be displayed on screens throughout the facility.

Employee engagement

Digital signage can enhance engagement by providing a platform for recognizing employee achievements, celebrating milestones, and sharing positive feedback. Digital signage can be used for training, offering instructional videos and updates on new procedures or technologies.

Strategies for Integrating Digital Signage

Assessing facility needs

The first step in integrating digital signage into a manufacturing facility is a thorough assessment of the facility’s needs. Are you aiming to improve communication, enhance safety, boost operational efficiency, or all of the above? Conduct a site survey to determine the best locations for digital displays, considering high-traffic areas, production floors, break rooms, and entrance points.

Choosing the right technology

Selecting the appropriate technology is crucial for the successful implementation of digital signage. Choose durable, high-definition displays that withstand dust, vibrations, and temperature changes. Ensure media players are reliable and handle various formats. Use a robust content management system for scheduling and remote updates. Consider scalability to meet future facility needs.

Integration with existing systems

To maximize the benefits of digital signage, it is important to integrate it with existing systems and data sources. This integration can provide real-time data feeds from manufacturing execution systems (MES), enterprise resource planning (ERP) systems, and other critical applications. By displaying inventory control databases and performance metrics, digital signage can offer valuable insights to employees and management alike.

Content management

The displayed content should be relevant, engaging, and updated regularly to keep employees informed and motivated. Automation tools can help streamline content updates, ensuring that information remains current without requiring constant manual intervention. It is important to establish a content review and approval process to provide quality control and ensure the accuracy of the information displayed.

Employee training

Training employees to use and interact with digital signage is essential for successful integration. Remember to educate all employees on how to interpret and act on the information displayed, such as responding to safety alerts or following updated procedures.

Maintenance and support

Ongoing maintenance and support are critical to ensure the digital signage system operates smoothly and effectively. Develop a maintenance schedule and a support plan that provides quick access to technical assistance when problems arise, minimizing downtime and disruptions.

Case Study

Successful implementation

The Millennium Print Group (MPG) case study exemplifies the successful integration of digital signage and automated systems within a high-volume manufacturing environment. MPG, a prominent producer of collectible and trading cards, faced significant challenges in managing its large contingent workforce and visitor registration processes. Leveraging friendlyway’s comprehensive hardware and software solutions, MPG transformed its manufacturing operations to enhance efficiency, security, and cost management.

MPG implemented friendlyway’s cloud-based platform with labor and visitor management, reporting, and integration modules. With 161 kiosks, 21 turnstiles, and 2 parking systems, they streamlined worker registration, check-ins, and access control. The system manages 600 temporary workers per shift, providing real-time attendance and activity reports. This was the best digital signage solution that reduced manual processes, improved security, and optimized workforce allocation, supporting MPG’s growing business needs.

Lessons learned

The successful implementation at Millennium Print Group offers valuable lessons for other manufacturing facilities considering digital signage integration:

1. Comprehensive needs assessment: By identifying pain points such as security concerns and inefficiencies in registration and check-in processes, friendlyway ensured the solution would address these specific challenges.

2. Choosing the right technology: MPG selected friendlyway’s robust hardware and software solutions, including 161 kiosks and 21 turnstiles, designed to withstand the manufacturing environment.

3. Seamless integration: Ensuring compatibility with existing systems and processes is vital. MPG’s integration of friendlyway Cloud Platform with its staffing agencies and security infrastructure demonstrated the importance of a cohesive, interoperable solution.

4. Effective content management for a more informed workforce: Automation tools and a clear content strategy helped MPG keep its digital displays dynamic and efficient to engage and inform the workforce more effectively.

5. The importance of employee training and engagement: MPG provided comprehensive training sessions that helped in the smooth adoption and effective utilization of new systems, leading to increased productivity and engagement.

6. Ongoing maintenance and support are crucial: MPG established a regular maintenance schedule and partnered with friendlyway for ongoing technical support.

By addressing these factors, other manufacturing facilities can replicate MPG’s success and harness the full potential of manufacturing digital signage to enhance operational workflows, communication, safety, and employee engagement.

Challenges and Solutions in Integration

Common challenges

Integrating digital signage in the manufacturing industry presents several challenges. One major challenge is the initial cost of purchasing and installing the necessary digital signage software and hardware. Ensuring compatibility with existing systems can be complex and may require custom integrations. Content management poses another challenge, as keeping the displayed information relevant and up-to-date demands continuous effort. Dust, vibrations, and extreme temperatures can affect digital signage hardware durability in manufacturing. Employee resistance and inadequate training can hinder successful implementation.

Overcoming obstacles

Manufacturers can manage costs with a cost-benefit analysis and scalable solutions. Invest in durable, industrial-grade hardware for longevity. Use experienced integrators and flexible technologies for easy integration. Develop a clear content strategy and use automation tools for updates. Train employees and communicate benefits to overcome resistance. Hold regular feedback sessions to address concerns and ensure a smooth transition.

Future Trends in Digital Signage Integration

Technological advancements

One key trend is the development of more durable and energy-efficient displays, such as OLED and microLED screens, which offer higher brightness, better color accuracy, and lower power consumption. Enhanced connectivity options, including 5G, will enable faster and more reliable data transmission. This will allow real-time computing to provide instant updates and remote management. Advancements in display resolutions, such as 8K, will provide clearer and more detailed data and information visualization, improving the effectiveness of information delivery.

Integration with emerging technologies

The integration with IoT allows for real-time monitoring and data sharing, enhancing operational efficiency, occupational safety, and health. Augmented reality (AR) and virtual reality (VR) are also being explored for training and simulation. AI-driven analytics can adjust displayed content based on real-time data and user interactions, optimizing communication and engagement. As these technologies evolve, they will further revolutionize digital signage in manufacturing, driving innovation and efficiency.

Conclusion

Using digital signage for manufacturing facilities helps boost efficiency, communication, safety, performance monitoring, and employee engagement. Strategic planning and adopting trends like AI, IoT, and advanced displays enhance its impact, driving continuous improvement and long-term success.