With the onset of the Fourth Industrial Revolution, characterized by the fusion of advanced technologies such as IoT, artificial intelligence, 3D computer graphics, and robotics, digital signage has become pivotal across various industries. Unlike static signs, digital displays can provide real-time updates, adapt to changing conditions, and offer animation and interactive menus on touchscreens that engage users more effectively. From critical safety warnings to operational instructions and performance metrics, factory digital signage is vital in maintaining a secure and productive workplace.

The Evolution of Factory Signage

Factory signage has come a long way from simple painted boards and static signs. In the past, signs were often limited to basic instructions and warnings, with little room for flexibility or real-time updates. As technology advanced, so did the capabilities of factory signage.

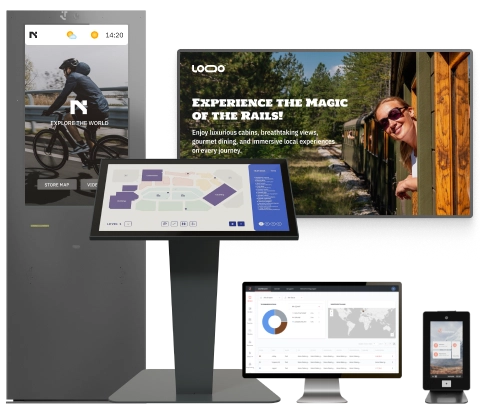

The introduction of electronic displays marked a significant shift, allowing for more dynamic content. Today, with the integration of digital technologies, manufacturing factory signage has become an interactive tool that can adapt to changing conditions, effectively grab employees’ attention, and provide instant news updates.

Besides, customers and visitors can benefit from digital wayfinding systems, which provide clear and interactive directions, helping them navigate the factory premises. They can also use analytics to track foot traffic patterns, optimize navigation routes, and provide insights into visitor behavior, further improving the efficiency of the signage.

The Importance of Safety in Factory Signage

Effective signage plays a critical role in ensuring a secure working environment. Factory signage serves as the first line of defense against accidents by clearly communicating hazards, emergency procedures, and safe practices. The importance of safety signage has only increased, as digital displays can provide real-time alerts and updates, ensuring workers are immediately informed of any changes in safety conditions. This can significantly reduce the risk of accidents and injuries, making safety signage an indispensable component of a comprehensive workplace safety strategy.

Compliance with safety standards

Traditional signage often falls short of maintaining up-to-date information, leading to potential gaps in compliance. Digital signage addresses this challenge by offering the flexibility to instantly update and display the latest safety protocols and regulatory requirements. This dynamic capability ensures that all safety information is current, reducing the risk of non-compliance and associated penalties for the organization. Moreover, digital factory and production signage can be customized to meet specific industry standards and local regulations, providing a tailored approach to safe communication for employees, customers, and visitors.

Real-time hazard alerts

One of the most significant advantages of visual factory signage is providing real-time hazard alerts. In an industrial environment, conditions can change rapidly, and the ability to immediately inform workers of new dangers can be life-saving. Digital signage systems can be integrated with computer networks, sensors, and other monitoring technologies to detect hazards such as gas leaks, machinery malfunctions, or fire outbreaks.

When a potential danger is identified, the system can instantly broadcast alerts across the factory, directing workers to safety protocols or evacuation routes. This real-time visual communication is crucial for minimizing response times and enhancing overall security, ensuring that workers are always aware of their environment and can react swiftly to avoid accidents. By combining compliance with safety standards and real-time hazard alerts, digital factory signage offers a comprehensive solution that significantly bolsters workplace safety and operational efficiency.

Enhancing Efficiency with Digital Signage

Streamlining operations

Digital signage can streamline factory operations by delivering precise and timely information to workers. Unlike static signs, digital displays can be updated instantly, ensuring employees receive the most current instructions and operational changes. This capability is particularly useful in fast-paced environments where production schedules, machinery status, and workflow priorities can shift rapidly.

Displays can also be integrated with elevator digital signage systems, inventory and warehouse management, and production tracking, to provide a holistic view of the operational status. This integration helps reduce downtime, optimize workflows, and improve overall productivity by ensuring everyone on the factory floor is aligned with the latest operational directives.

Real-time data display

The ability to display real-time data is a game-changer for factory efficiency. Digital signage can show live metrics such as production rates, equipment status, and quality control statistics. This immediate visibility into critical data allows for quick decision-making and prompt responses to any arising issues. For example, if a machine’s performance begins to lag, the real-time data displayed can alert technicians to address the problem before it impacts the production line.

Additionally, real-time displays can enhance transparency and accountability among workers, as everyone can see the current status and goals, fostering a collaborative and motivated work environment. By leveraging digital signage for real-time data display, factories can achieve higher efficiency, reduced errors, and more effective resource management.

Key Features of Effective Digital Factory Signage

Visibility and readability

Visibility and readability are paramount for digital signage to be effective in a factory setting. Signage must be easily seen by all workers, regardless of their location or the lighting conditions. High-resolution displays with bright, contrasting colors ensure the information stands out, even in dimly lit or brightly illuminated areas.

The text and symbols should be large enough to be seen from a distance, with unambiguous fonts, maintaining brand consistency while avoiding overly decorative styles that could impair employee and customer experience.

By ensuring high visibility and readability, digital signage can effectively communicate important messages, such as safety alerts, operational updates, and instructions using multimedia formats such as texts, images, or videos. This reduces the risk of miscommunication, which is vital in maintaining a safe working environment. Enhanced readability also contributes to operational efficiency, as workers can quickly and easily understand the displayed information.

Durability in industrial environments

Durability is another crucial feature of effective digital factory signage. Industrial environments can be harsh, with exposure to dust, moisture, vibrations, and temperature fluctuations. Digital signage must be robust enough to withstand these conditions without compromising performance. This includes using weatherproof and dustproof enclosures, rugged materials, and protective coatings to safeguard the electronic components from environmental hazards.

Signage should have shatterproof screens to prevent damage from accidental impacts and anti-glare coatings to maintain visibility under various lighting conditions. Ensuring durability not only prolongs the lifespan of the signage but also maintains the reliability of the information being displayed, which is essential for maintaining consistent safety and operational efficiency.

Regular maintenance and inspections further ensure that the signage remains in optimal condition. By prioritizing durability, factories can avoid frequent replacements and downtime, ensuring that critical safety and operational messages are always communicated to workers, thus enhancing safety and productivity.

Customizability and flexibility

Each industrial setting is unique, with different requirements for information display. Digital signage should offer customizable content options, including specific instructions, safety alerts, and operational data relevant to the factory’s operations. The ability to quickly update and change the content is also crucial, providing the flexibility to respond to real-time events, production changes, and evolving operational needs.

This agility ensures that the most pertinent information is displayed, enhancing safety and efficiency. Furthermore, proper factory signage design ensures smooth integration with existing factory software, such as production management and safety monitoring systems. This allows for automation based on real-time computing, ensuring that workers are always informed of the latest data updates, which is vital for maintaining a streamlined and safe working environment.

Integration of Digital Signage with Factory Systems

IoT and smart factory integration

The Internet of Things (IoT) plays a pivotal role in digital signage integration with factory systems. IoT-enabled display devices and sensors collect vast amounts of data from all factory parts, such as equipment status, environmental conditions, and production metrics. By connecting digital signage to these IoT networks, factories can display real-time information, ensuring that workers are immediately aware of any changes or issues. For example, if a sensor detects a malfunction in a machine, the digital signage can instantly alert technicians, minimizing downtime and preventing potential safety hazards.

Centralized control systems

Centralized control systems further enhance the integration of digital signage in factories. These systems allow for the centralized management of all digital displays, providing a unified platform to control and update content across multiple signage points. This capability ensures consistency in the communicated information and simplifies managing and deploying updates. Centralized control also enables quick adjustments to signage content in response to real-time data, enhancing safety and efficiency by providing accurate and timely information.

Conclusion

The advent of digital signage has revolutionized how information is conveyed in different environments — you can see digital signs on the schedules in airports and bus stations, and they are widespread on billboards in healthcare, education, retail, and advertising industries. In the current information age, the manufacturing industry also significantly benefits from this technology.

Digital signage experience offers real-time updates, dynamic content, and interactive capabilities, far surpassing traditional static signs. Integration with IoT and centralized control systems ensures timely and accurate information, promoting a safer and more efficient work environment. Key features such as visibility, durability, and customizability are crucial for effective implementation, increased productivity, and revenue.

As factories embrace digital transformation, digital signage will continue to play a pivotal role, creating a responsive and safe industrial landscape that meets modern demands and paves the way for future innovations.